What's on the agenda in 2021?

Investments are an important factor for the continued existence and future viability of a company. Continuous modernization ensures the maintenance, improvement or expansion of production equipment and helps us to remain competitive and become more environmentally friendly and efficient. Investments are planned well in advance in order to build up appropriate reserves and, for example, to plan for planned machine downtimes in the production.

With over 80 machines, from the small milling machine in our training workshop to the vertical centrifugal casting machine, WALZEN IRLE has an enormous machine park to manage.

In recent years, WALZEN IRLE has had a wide range of investments on its agenda: a new heat treatment furnace, which will allow us to reduce our CO2 emissions by nearly half of the old furnace, was put into operation last year, the relocation of our two mold boring machines is being prepared, and the complete conversion to LED lighting is still in the process of implementation. The retrofit will save hundreds of thousands of kWh of electrical energy, improving the sustainability of the company.

Further major investments have been planned for this year.

2021 will see the rebuild of our largest CNC roll grinding machine, which has been planned for many years. With an estimated downtime of the grinding machine of over five months, this is a project that must be planned down to the smallest detail and requires a high level of project management. This rebuild affects especially the grinding capacities of the big calender rolls. Many months before, the planning of our production had to be checked exactly, so that the big calender rolls could be finish ground in advance. At the same time we did a re-planning of capacitities of already booked orders on our other internal grinding machines.

At the end of January, the machine was dismantled in order to realign it, provide it with a new state-of-the-art CNC control system, new motors and measuring equipment. The machine will undergo a complete overhaul and will also receive a new coat of paint. The new control system and modernization of the entire machine guarantee that we will continue to meet the high requirements and allow forward-looking developments in the field of the roll production. Most of this work is done by our own maintenance department. Due to the good planning and the smooth run-up of the modernization, we will probably be able to complete the work at the end of May.

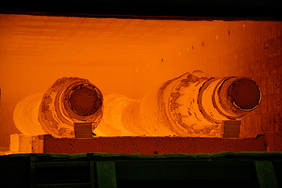

Another major investment is planned for the second half of this year. A new ladle heating system is going to replace an outdated system. A homogeneous, time and energy saving, as well as environmentally and material friendly heating shall be guaranteed. We expect this to result in CO2 savings of 110t/year, which will again improve our CO2 footprint.

In addition to material investments, we naturally also see our trainees and employees as an "investment in the future". For example, we have found a partner in the company HAMBL who supports our trainees throughout their entire training period with the holistic personality training "G.E.D.A.N.K.E®" in the further development of their potential.

We will report in detail on the investments and projects in the near future.