Rolls for the paper industry

Technological competence in the production of rolls for paper machine calenders

We are an original parts manufacturer (O.E.M.) for all calender types in use and have at our disposal roll concepts for the complete production spectrum of the paper industry like graphical, cardboard- and packaging, tissue and special paper. We develop and manufacture oil heated, water heated and cooled thermo rolls with optimal properties as individual solutions for customer specific requirements.

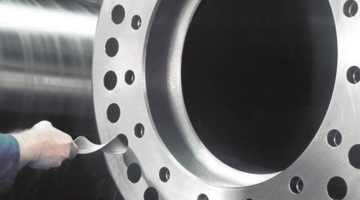

A flawless and precise roll geometry, uniform temperature distribution, accuracy of surface and mechanical characteristics are the key factors for the highest product quality and marketability of your product.

Starting with sophisticated design, through the use of the most modern materials for castings, through completion by extensive heat treatment facilities, i-hardening, hot grinding, finishing and superfinishing - our rolls satisfy the highest expectations.

Roll concepts

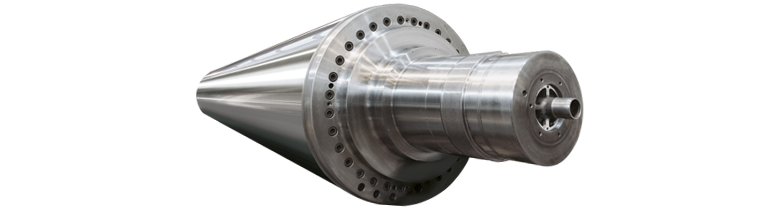

Thermo rolls

Heated thermal calender rolls with peripheral bores for optimal heat transfer from Walzen Irle utilizing the well known flow principles MonoPass, DuoPass or TriPass can be found in all types of calenders, in hardnip calenders, in super- and softnip calenders as well as in offline or online operating multinip calenders.

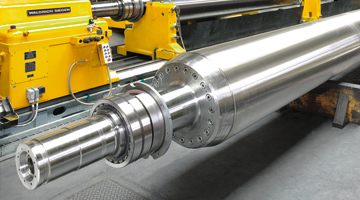

Calender rolls

Conventional calender rolls are used in two- or multi-roll-calenders as unheated, solid poured with integral or bolted on journals. We manufacture replacement rolls with improvements in material and production.

Roll shells

We manufacture the shells for multi-zone rolls and swimming rolls in various materials such as chilled cast iron, the modified chrome cast iron material KSTV or hardened forged steel. For soft covered rolls the shells are normally made of grey iron or nodular iron.