Innovations and patents

As evidence of our intensive efforts to effectively support our partners in paper and plastic industry, we own more than 20 patents and innovations which we have developed in the calender roll sector.

Following we present some of our developments and patents.

Overview

Mechanical machining

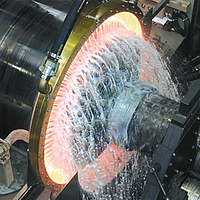

Hot grinding

In order to eliminate concentricity deviations and edge deformation of the thermo rolls during operation the hot grinding process has been developed and implemented in our production. The rolls will be heated up to the respective operating temperature of the production calender, will then be ground to shape and finish machined at a temperature which reflects the medium operating range of the calender.

Deviations of concentricity and shape at operating temperature are reduced to a minimum.

Furthermore calenders running with rolls manufactured using this grinding procedure show a higher performance and provide better quality products than with conventionally machined rolls.

i-Hardening

i-hardening is a special thermal process which has been developed by us for hardening of the roll surface in order to achieve a quality improvement of the calender roll. The achievable hardness is dependent on the material and the tempering temperature (exact specification is required).

Advantages:

- the induction hardening process provides a very homogeneous concentric hard layer which gives the roll an excellent run out behavior

- results in highest values of roll characteristics

- best run out at hot operation of rolls

- opposed to a hard coating or the hard layer of a standard chilled cast iron roll the induction hardening procedure will not create a thermal insulation

- reduced residual stresses

- potentially the roll can be re-hardened when the initial layer is ground off

Dynamic hot balancing

The target of the WALZEN IRLE „hot balancing process" is to optimise the operating behaviour of thermo rolls under specific operating temperatures and speed ranges during the balancing process. Cold balancing of rolls without considering operating parameters may compromise quality results.

S-Technology

Minimize barring and polygon effect

Middle of the 1980´s WALZEN IRLE established peripherally drilled rolls for the paper industry. This was an important step towards higher temperatures on roll surfaces.

The impulse to develop the WALZEN IRLE S-Technology was to further improve the transition of thermal energy from the peripheral bores to the roll surface. The thermal transfer is improved by spindles (turbulators) inserted into the peripheral bores which force the heating medium into a spiral motion thus increasing the speed of the fluid and the area it is passing by.

WALZEN IRLE S-Technology is applicable for every peripherally drilled roll type as a basic feature and also for upgrading existing rolls. Using the S-Technology tolerances for temperature and shape accuracy can be reduced by up to 50% compared to conventional peripherally drilled rolls.

Coatings / chrome plating

Thermal rolls made of forged steel

The requirements for thermo rolls have increased extremely in recent years. A real innovation has been thermo rolls made of forged steel with carbide or ceramic coatings. The technology has been developed by WALZEN IRLE together with the S. D. Warren Company. We acquired the exclusive rights to manufacture and market the rolls of the S. D. Warren Company, today known as Sappi Fine Paper North America.

Chrome plating / thermal coating

If a surface coating or plating is required we can provide a hard chrome plating or a thermal spray coating according to customer’s application.

Variable edge insulation

Optimal behavior of calender rolls

To maintain optimal behaviour of the calender rolls even with varying paper widths an individually adjustable edge insulation is the logical consequence in order to avoid overpressing of the paper edges. WALZEN IRLE has developed a system to adjust the size of the edge insulation without having to dismantle the roll.

The adjustment can be done via one central bolt on the outside of the roll for all insulation pipes at once.

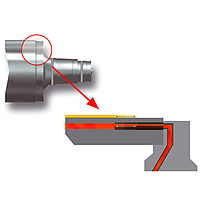

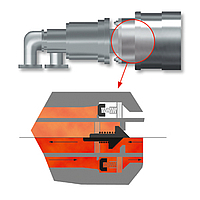

IRLE-Autolock-System

Reduzierung von Stillstandzeiten

The Auto-Lock-System for heated calender rolls is an innovation of WALZEN IRLE which serves the reduction of shut down times for maintenance and repairs increasing operating safety at the same time.

The Auto-Lock-System consists of a valve which seals the heating medium (oil or water) in the roll during roll change, other maintenance work or in case of a pressure drop i.e. breach of a hose to the rotary joint.

It is possible to update your existing roll with the IRLE Auto-Lock-System.

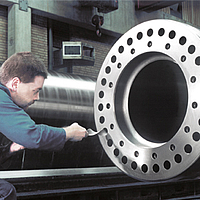

Rapid service journal

Technical and handling benefits

The patented new maintenance friendly, roll journal comes with 5 technical and handling benefits:

- Sealing and bearing function are decoupled. Maintenance work on the roll does not require the dismantling of the whole journal. Time consuming rebalancing or regrinding is not necessary.

- An update of existing rolls with the WALZEN IRLE variable edge isolation is possible.

- Under high operating temperatures calender rolls made from chilled cast iron tend to thermal bending (bi-metal effect). The IRLE journal allows a thermal straightening of the roll. Balance and runout will be improved and provide the best possible paper quality for you.

- The new journal from WALZEN IRLE uses special flat seals for temperatures up to 450 degC. Surface temperatures can be brought to levels never seen before.

- The WALZEN IRLE rapid service journal allows the use of flexible balancing weights. They can be adjusted to every position on the journal´s edge. Balancing is much easier and quicker than with conventional journal designs.