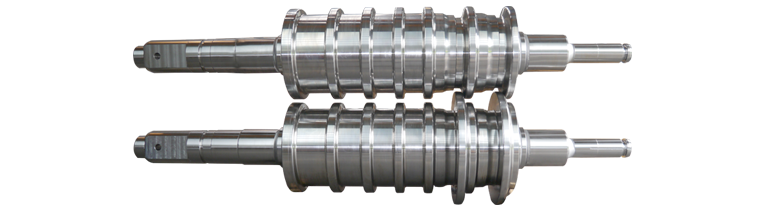

Section mill rolls for the production of long products

Rolls for fine section mills, middle section mills, large section mills, tube rolling mills, wire rolling mills and bar rolling mills

The main customers for long products are building-, construction and machine-, ship building-, commercial vehicle-/automobile industries as well as the railway sector.

To determine the suitable roll material for section mills, material properties have to be adapted to the specific rolling mill conditions. The following essential points have to be taken into consideration:

Roll factory conditions:

- type of stand

- product to be rolled

- mechanical demands (rolling pressure, driving torque and stock-reduction)

- roll calibration (initial pass and finish pass, bite angle and max. depth of pass)

- temperature demands (rolling temperature, -speed, roll cooling)

Properties of the roll material

- mechanical properties (tensile- and bending strength, high thermal strength, modulus of elasticity)

- surface hardness - radial hardness drop

- wear resistance

- fire-crack resistance

- gripping capacity (friction coefficient)

- oxidation stability