Roll service

Maintenance and repair should ensure the highest possible technical availability of facilities. In the recent years, many companies removed from the idea, that maintenance is only a necessary evil and only causing costs. The know-how is the main source of a professional maintenance.

Through many years of experience and the most modern equipment, a wide range of roll repairs, preventive maintenance and various modernizations can be offered.

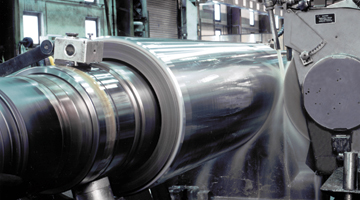

WALZEN IRLE focuses on the service for rolls for the paper, plastic and food industry. Through years of experience we understand the wear behavior of rolls and the repair and optimization options very carefully. We can optimize measurable the efficiency and productivity of existing plants.

Our range of services

Machining feasibilities

- max. roll diameter 2.000 mm

- max. roll face length 12.000 mm

- max. weight - up to 120 tons

Roll refurbishment

- Machining and measuring of rolls and roll simulation under operating temperature

- Warm or cold dynamic balancing

- Cleaning of rolls incl. the peripheral bore system

- Replacement of o-rings and sealings

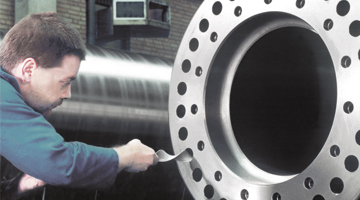

- Roll inspection

- Roll covers and roll coatings

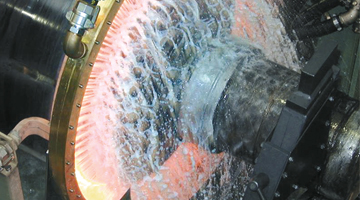

- (Re-) hardening of forged steel rolls

Grinding service

- All conventional kinds of roll grinding

- Special grinding of roll shapes

- (Super-) finishing of the roll face

- Re-grinding of rolls in cold condition and under operating temperature for correction of the roll

- geometry like run-out, etc.

- Grinding of coated and covered rolls

Measurements, analysis´ and inspections

- Run out / vibrations

- Shape of the roll face

- Bearing seats

- Surface hardness

- Roughness of roll surface

- Temperature distribution across the roll

- Assessment of the chemical composition

- Inspection of damages

- Ultrasonic tests

- Crack tests

- Metallurgical analysis

- Determination of the material properties by non-destructive and destructive tests

Modernization

- Rebuilding of non-heated rolls into heated rolls

- Rebuilds of displacer type rolls to peripheral bores

- Optimization of peripherilly drilled rolls (for example the "S-Technology" to improve the heating capacity)

Repairs

- Plugging of small surface defects

- Grinding of cracks

- Metal spraying and re-grinding of bearing seats

- Boring and re-honing of roll shells

- Thermal alignment

- Repair and/or exchange of journals

Technical consultation in case of

- Questions of roll wear

- Determination of roll crown

- Roll damages

- Roll configurations

- Roll modernizations

Spare parts

- Siphon pipes

- Sealings, o-rings, gaskets

- Screws

- Roll plugs

- Flanges